Elastomeric roof coating adds years to a commercial roof’s lifespan, reduces energy costs, and provides strong protection against the elements. It saves money and protects against leaks.

However, there are key factors to consider that will help you make an informed decision on whether or not elastomeric is the solution you need. We’re here to walk you through all of them.

What is an Elastomeric Roof Coating?

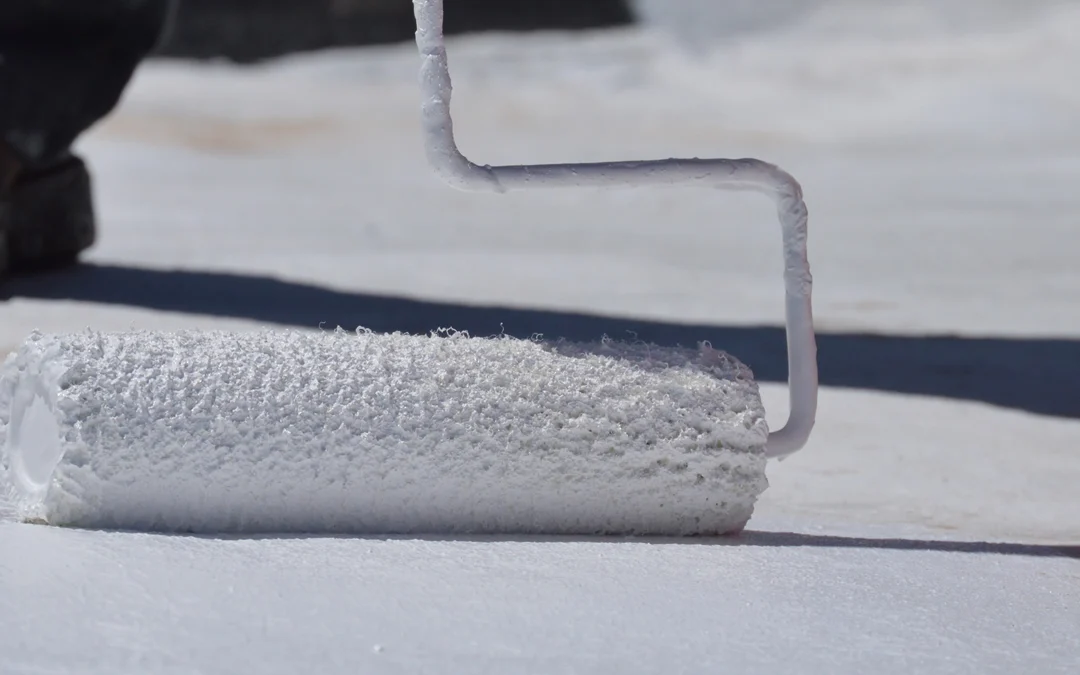

An elastomeric roof coating is a liquid applied on top of existing roofs. The liquid has polymers that exist in an amorphous state (no defined shape), allowing it to bond easily where it’s applied.

They come in two parts—solids and carrier. Some materials like silicone mostly have solids. Acrylic is almost half carrier and half solid. We’ll get more into this later.

The elastomeric coating creates a solid, unbroken, and flexible membrane when it cures. Leaks are sealed, existing damage doesn’t worsen, and old roofs get a breath of new life.

Elastomeric roof coatings come in white to help deflect UV rays or gray to trap heat during cold months. There are four types to consider: silicone, acrylic, polyurethane, and butyl.

Types of Elastomeric Roof Coating Material

When it comes to elastomeric coating, there are different types of roofing materials to choose from. Each elastomeric roof coating material is formulated to suit different roof types, environments, and weather conditions. Here’s a rundown of what to look out for:

Silicone

Silicone is one of the most popular elastomeric roof coating materials. It’s 96% solids and 4% carrier. When it cures, most of the material stays. This makes it durable and water-resistant.

If you have a flat roof, silicone is your best bet since they’re able to handle pooling water without evaporating the material. The only downside is the cost, which is why many go with acrylic.

Acrylic

Acrylic coatings should be used for sloped roofs. It can’t handle pooling water. That’s because it’s 52% solid and 48% carrier by volume. The upside? It’s more affordable than silicone.

Evaporation leads to nearly half the applied product getting lost. You need more of the material to compensate for this issue. But it’s still more cost-effective if you have a sloped roof.

Aside from affordability, acrylic also has great insulative properties. Property owners with acrylic elastomeric roof coating can expect lower energy bills, making it the most used type of coating.

Polyurethane

If you’re looking to add durability to your roof, polyurethane is the way to go. It’s the perfect coating for roofs that get a lot of foot traffic and ponding water.

Polyurethane is also a great solution for roofs with single-ply TPO, PVC, or roofs made from modified bitumen. It can even handle contraction and expansion due to heat and cold.

This makes polyurethane a solid elastomeric roof coating for a lot of circumstances. However, polyurethane is xylene-based, requiring specific equipment and careful application.

It’s not a material that’s fit for a DIY project. If you want to properly apply polyurethane, it’s best to call a professional roofing company.

Butyl

Butyl is created from isobutylene that’s refined to create butyl rubber. It’s then transformed into a liquid form and used as an elastomeric roof coating.

Property owners use this type of elastomeric roof coating on roofs made with asphalt, modified bitumen, or single-ply roofing. Unlike acrylic, it handles pooling water on low slopes or flat roofs.

Butyl is highly flexible, impermeable to air, and can create a vapor barrier, which helps prevent interstitial condensation on your roof. The downside is that it’s not environmentally friendly.

How Much Does Elastomeric Roof Coating Cost?

\Your budget ultimately decides what you can go for. On average, elastomeric coatings cost between $14 to $65 per gallon depending on the material or where you’re located.

Labor costs should also be considered. Although elastomeric coatings are applied like paint, they still need proper application and equipment. It’s best left to the professionals.

If your roof is old but still in decent condition, applying elastomeric roof coating becomes a better investment than getting a new roof installed.

Elastomeric Roof Maintenance

Maintaining your roof after applying elastomeric coating significantly extends its lifespan. In the first one to two years after application, your roof can get dirty.

“Chalk,” a powdery byproduct of elastomeric roof coating exposed to UV rays can also build up. This is natural. But it can be damaging if left unchecked.

Debris can cause small splits, cracks, and tears on your roof. Repairs on minimal damage are simple, only requiring you to clean the area, dry it, and apply an additional layer of coating.

When you’re close to the 10-year mark, look for signs of the existing substrate showing. You’ll know when the coating is gone when a black look can be seen through the coating.

Types of Elastomeric Roof Coatings

Elastomeric roof coating prevents existing damage from worsening, seals roof leaks, and extends the lifespan of your commercial roof. To help you make an informed decision, here’s a quick rundown of the most popular elastomeric roof coating materials:

- Silicone: Best for flat roofs since it’s durable against pooling water. Can be expensive but offers a well-rounded solution against water damage and UV rays.

- Acrylic: The most popular elastomeric roof coating material due to its affordability and insulative properties. It’s best used on sloped roofs.

- Polyurethane: Mostly used on roofs with a lot of foot traffic. Commonly uses xylene-based materials and requires specific equipment to apply.

- Butyl: It’s a flexible and durable elastomeric roof coating material and prevents interstitial condensation. The downside is that it’s not environmentally friendly.

No matter what type of elastomeric roof coating material you choose, it’s best to leave the application, maintenance, and repairs to the professionals. Thinking of applying elastomeric roof coating to your property? Request a free estimate with Trenton Roofing and Siding today.

Alex Valentino – Vice President

Leading the way for the company’s second generation of family and employee ownership, Alex’s mission is to create lasting relationships built on trust and respect by providing uncompromising workmanship and unparalleled customer service. With a focus on safety and consumer education, Trenton Roofing strives to set the bar for the advancement of the roofing industry and the betterment of our local communities. When he is not working, Alex can be found traveling with his fiancée, watching football or playing a relaxing round of golf with his friends.

Recent Comments